More than

a Ladder language

Ladder standard language is strongly

rigid. Components must be forced in predeterminated cells along two rails

called rungs. Moreover Ladder standard language has great limitations

about feedback connections. LadderWORK broken these limitations introducing

the first free schematic ladder diagram. LadderWORK includes a powerful

schematic editor. Components can be placed anywhere and there isn't limitation

on feedback connections. LadderWORK schematic is more similar to an electrical

circuit. Moreover LadderWORK includes extra components like logical ports

and flip-flops so if you are well-versed in boolean logic you can approach

your problem using these traditional notation.

Electrical notation

approach

LadderWORK is remarkably intuitive!

With LadderWORK you haven't to know nothing about assembler, interrupts

or hardware architectures. All you have to do is think your project as

a electrical scheme where you have to disposition switches, relays and

lamps. Switches means inputs, lamps means outputs and relays gives the

way to create states and elementary memory cells. Many problems related

to control automation can be resolved in few minutes using LadderWORK.Put

a PLC into your microcontroller! With LadderWORK you can transfrom a microcontroller

in a PLC . Microcontroller support is activated simply selecting your

MPU model during project setup. For example if i select the 8051 MPU the

system put to disposition all the 8051 chip I/O resources. So when i configure

my input or output devices i directly see the resource named P.0 .. P.7

which means that the system will drive the relative hardware pin. Full

8051 ADVANCED version includes USER FUNCTIONS so if you need a particular

device you can write your assembly routine for your needing.

LadderWORK run-time kernel is really small and the system requirements

are minimum. For example, in a 8051 system the hardware requiments are

just the TIMER 0, used for global timing, and less than 20 bytes of internal

RAM including stack area.

8051 version of LadderWORK can be configured to use internal or external

RAM with customizable memory mapping.

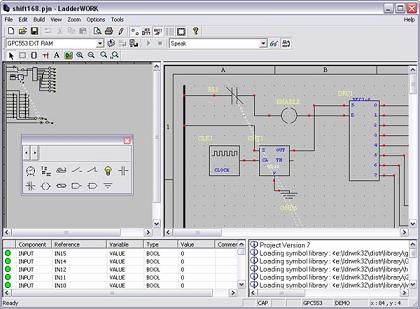

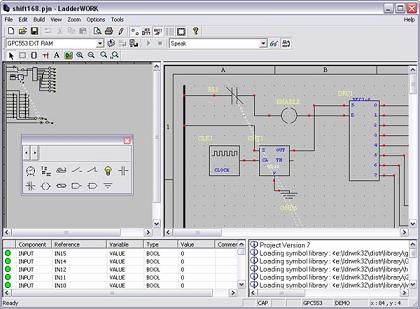

The LadderWORK Integrated Development Environment (IDE)

The picture below, represents the apperance

of the program LadderWORK on your computer. LadderWORK has an integrated

environment feature, allowing you to draw schematics, compile programs

and upload code to PLC always working on the same window. The integrated

environments are composed by several parts described below.

Customizable Code Generation

& Linker parameters

The 8051 microcontroller has an amount

of RAM inside the chip. Normally this RAM array is 64 to 256 bytes. The

8051 can address an external RAM bank up to 64KBytes. LadderWORK can be

configured to use the internal memory, the external memory or both. With

LadderWORK you can easily create your custom mapping/compiler setting

to fit the your embedded board requirements and save it in files called

profiles.

| LadderWORK software

integrated extra features |

| |

Watching and probing capability: The

variables related to the objects placed in the schematic could be

watched. During PLC running a watch window will show real-time,

the value of this variables. Also, the nodes in the schematic could

be probed. Placing the probe component in a particular node will

show the value of the node during running. Note that these feature

will require a dedicated serial port. |

| |

MODBUS Protocol: LadderWORK integrates MODBUS(R)

RTU protocol. You can use the protocol to read or write data from

and to the PLC. This feature allow you to connect your devices

to SCADA and SUPERVISION systems |

| |

Customizable Code Generation & Linker parameters: You

can use LadderWORK as a generic ladder compiler for 8051 microcontrollers.

Code generations and linker options can be adapted for your own system |

| |

HMI & MMI: LadderWORK integrates the possibility

to create HMI (Human-Machine-Interface) or MMI (Man-Machine-Interface)

directly with the using of dedicated components like DISPLAY and FIELD.

The HMI kernel allow you to drive up to four distinct character-based

operator panel. |

| |

|

Next software

features

For the future a lot of new features

will be implemented in LadderWORK software.

IEC 1131-3 Compliant function blocks

: Our goal is to meet the IEC / CEI 1131-3 standard. A lot of new standard-compliant

function blocks will be ready in the next issues of the software.

IMPORTANT

: Since January 2002 the software package don't

includes paper manuals ( PDF & Electronics format only )

Download a functional demo of LadderWORK now!

Other related documents

| File Name |

Description |

Size |

| applw008.zip | APPLW008 - MODBUS 8x8 extension

This application note demonstrate how to realize a complete 8 inputs / 8 outputs MODBUS extension (RTU mode protocol) using LadderWORK. The project can be easily transferred on any 8051 core with a simple UART hardware on-board. The application note is complete of documentation and sample project. | 141KB | | applw002.zip | A/D Converter with histeresis sample circuit

This application note shows how to add an histeresis behavior to an A/D circuit. The project is based on the standard AD_CONV component and requires just five components | 115KB | | applw004.pdf | Using CMP_W magnitude comparator

This document is related to the using of CMP_W component (Magnitude comparator) | 68KB | | tchlw007.rar | Making your own designed PLC with LadderWORK

This document allow you to create you 8051-based PLC teaching you how to customize LadderWORK software | 6MB | | tchlw008.pdf | Making a LED connected to a 8051 port BLINK!

This is your very first project with LadderWORK!

***** YOU CAN'T MISS IT! *****

What you need to try this project is just a 8051 chip and a LED connected to a port pin.

A REAL COMPLETE TUTORIAL to run your first LadderWORK project.

TRY IT! | 5Mb | | tchlw009.zip | Adding HMI Interface to your own PLC

This is a complete tutorial that helps you to add a complete HMI (Human Machine Interface) to your

LadderWORK based 8051 PLC

With this tutorial you learn how to add a custom DISPLAY and KEYPAD to your system

| 1.8Mb |

| LadderWORK Software package includes: |

| |

CD-ROM with self-extract installation & Electronic

PDF documentation |

| |

Hardware dongle key (Parallel or USB) |

| |

Product registration form (PRF) |

| |

Quick reference for the main components |

| |

|

Links/Web resources

| |

Description |

Go! |

|

View LadderWORK presentation at GRIFO web site site |

... go to link

|

|

View LadderWORK presentation at Sample Electronics web site |

... go to link

|

|